Oregon State University, Forest Science Complex

The College of Forestry at the Oregon State University provides a new learning environment for the Forest Sciences Complex in Corvallis, Oregon. The Forest Sciences Complex comprises of three distinct but interconnected buildings – a new Peavy Hall, a new Advanced Wood Products (AWP) Center and ancillary spaces in the existing Richardson Hall.

Peavy Hall provides innovative classrooms, research laboratories, administration offices, and faculty offices, that allow students and researchers to explore the vibrant wood industry in Oregon and beyond. The cutting edge mass timber building combines exposed wood throughout, with post-tensioned CLT rocking shear walls; an innovative design and a first in North America, which significantly reduces the earthquake loads on the structure, providing a highly resilient, immediate-occupancy building.

The Center for Advanced Wood Products (AWP) provides dedicated research spaces for developing and testing advanced wood products and leading-edge wood technologies. Reimagining the familiar pre-engineered steel shed, the 20,000 SF Laboratory uses exposed timber in an industrial setting, which has proven to be both practical and uniquely pleasing for occupants. The building which showcases a number of timber products, utilizes Mass Plywood Panel (MPP) shear walls, another first use in North America.

-

Location

Corvallis, OR, US

-

Completion Date

2020

-

Area (SF)

20,000 SF (AWP)

-

80,000 SF (Peavy Hall)

-

Typology

Institutional, Higher Education

-

Architect

Michael Green Architecture

-

Awards

See Project Pages

Process

WOOD-CONCRETE COMPOSITE

With over a decade of incremental research into the use of wood-concrete composite structures and having designed some of the largest applications of the technology in the world, we have now honed our expertise in the use of this innovative technology.

The upper floors of the 83,000 sq.ft. 3-story T-shaped Peavy Hall combines exposed CLT solid wood floor panels with a thin site poured concrete topping supported on double glulam-concrete composite beams spanning 40 feet. The Atrium wing on the third floor, uses CLT-concrete composite panels spanning 36 feet without intermediate beams, achieving a structural depth of just 14”.

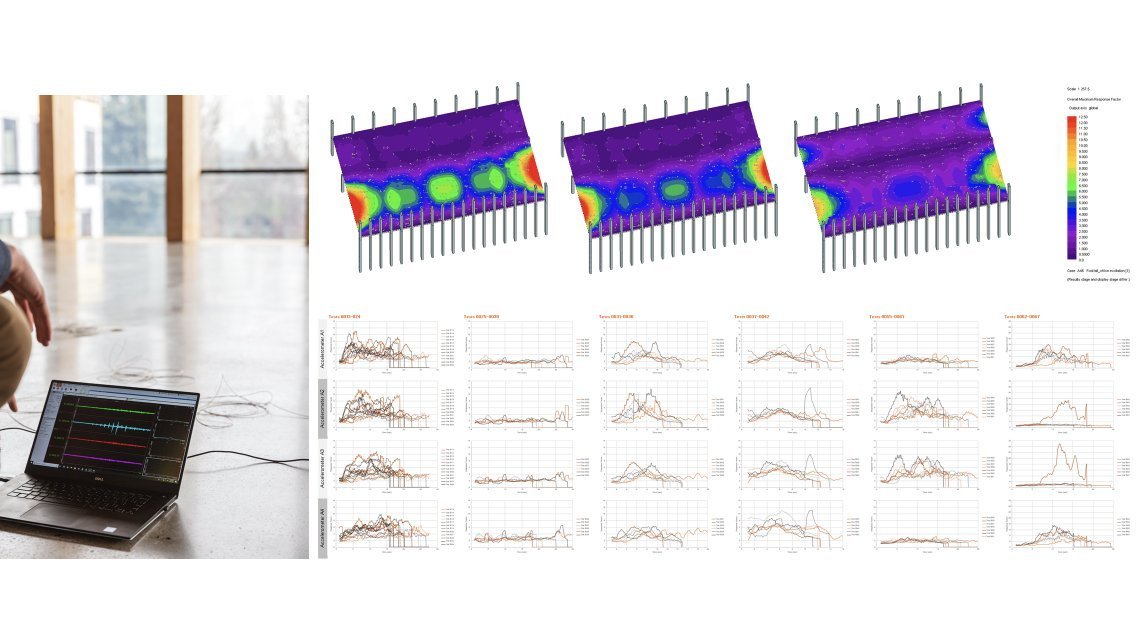

VIBRATION AND ACOUSTIC TESTING

Equipped with new tools to evaluate dynamic performance with in-situ testing, Equilibrium developed and undertook a testing regime to validate design assumptions and calculations with real world performance data.

Similarly, the high-performance sound resistance requirements of the exposed structural assemblies using a combination of concrete topping, acoustic mat, and mass timber panels could be proven.

This provided invaluable firsthand knowledge as to how our design was performing in a real building setting, an area where the industry is lacking information. This allows us to push the limits of structural design, while still meeting the vibration and acoustic requirements of the buildings we design.

CLT ROCKING SHEARWALLS

Being on the Pacific North West coast the seismic demands of the site are particularly severe.

Recognizing the opportunity to support and demonstrate the latest in timber innovation, this building features an innovative self-centering post-tensioned rocking shearwall system for the first time in North America.

The system uses unbonded post-tensioned rods within 7 ply CLT wall panels, which allow the base of the walls to rock in a seismic event and return to their original position. Energy dissipation is provided by dampers, which consist of “U” shaped bent steel plates that deform as the wall rocks back and forth in a seismic event, and can then easily be replaced.

The post-tensioning forces are tuned to provide a self-centering system, creating a highly resilient, low damage, immediate-occupancy building. This is in stark contrast to a conventional shear wall system that would typically experience significant damage and require replacement after a seismic event.

This low damage approach to seismic design adds a level of protection against changing design codes, making the building inherently sustainable and offering exceptional value to the client.

FEATURE STAIRCASE AND ATRIUM SPACE

The structural use of timber that is left exposed is celebrated throughout the building.

In the Atrium, expressive double-height glulam fin columns are used to provide sun-shading and support for the full height glazing system.

The feature staircase uses glulam treads reclaimed from the original Peavy building, and is fully detailed with concealed connections, underlining the natural beauty of the timber material, and providing a fire-resistant exposed structure.

ENVIRONMENTAL SUSTAINABILITY

The specification of wood from FSC managed forests as the primary building material was a major driver underpinning the design. The structure is built from Douglas fir sourced locally and fabricated less than 500 miles from the site.

Much of the exterior is clad in Oregon Red Alder which has been modified through a process called acetylation to increase dimensional stability and resist rot, reducing maintenance and increasing service life.

These thoughtful design choices will significantly reduce embodied carbon impacts over the building’s life as the sustainably managed forests from which the timber was selected continue to absorb atmospheric carbon.

LIFE CYCLE ASSESSMENT

Global Warming Potential 437,642 kgCO2eq

Global Warming Potential per area 57 kgCO2eq/m2

For this project, concrete makes up a small portion of the superstructure by volume, but accounts for about 74% of the GWP.

Our life cycle analysis takes account of the wood sequestration over the lifetime of the building, which helps offset the embodied carbon in the concrete.

ADVANCED WOOD PRODUCTS LABORATORY (AWP)

The 20,000 sq. ft. Advanced Wood Products Laboratory is home to the TallWood Design Institute, which brings together industry and academia to advance knowledge about the use of wood products in buildings through applied research, product development, and professional education.

Following our previous successes to reimagine pre-engineered steel buildings with wood, exposed timber in an industrial setting has proven to be both highly practical and uniquely pleasing for its occupants.

Using wood in an industrial setting presents several opportunities for integrating structure with the building systems, which must remain exposed for access and alteration of shop equipment in the future.

AWP STRUCTURAL SYSTEM

Standard dimensional lumber joists span between long-span glulam beams, which in turn bear on double-height glulam columns that also support the shop cranes. The glulam sections are slightly tapered to optimise the use of materials and provide roof drainage.

Lateral resistance is provided by exposed steel rod bracing and Mass Plywood Panel (MPP) shear walls, the first use of this new locally produced mass timber panel product.

The roof of the lower area is framed with timber joists supported on light-frame stud walls, with glulam beams and columns at the front entrance of the building.

A reinforced concrete strong wall and strong floor was designed to the clients high loading requirements and extremely low deflection limits, creating a state of the art material testing facility.